Your pre-connected intelligent automation solution, the Laguna smartBOX features flexile configurations, comes pre-wired, is custom designed to every customers exact requirements, and is all backed by our industry leading car wash technology professionals.

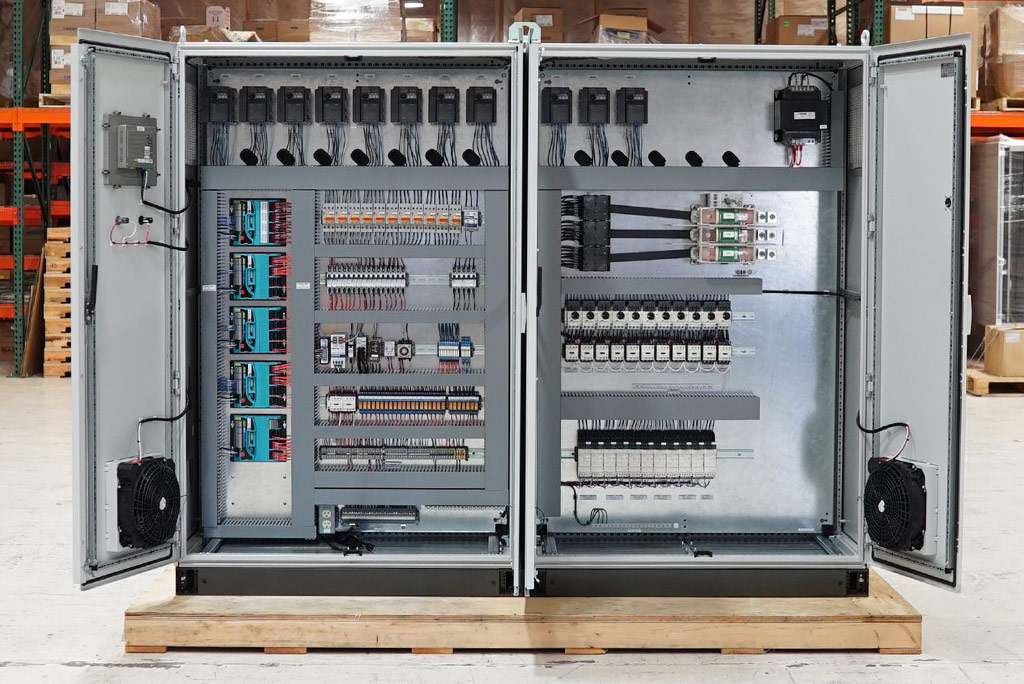

smartBOX Motor Control Center

Think Inside the Box - There is a lot more going on in there than you know.

Choose Your Configuration:

- Laguna rTC with integrated smartBOX MCC

- Integrate smartBOX with any tunnel controller

- Stand-alone motor control center (MCC)

Integrated Smart Technologies

smartBOX offers fault monitoring and phase protection to minimize wear to motors, pumps, and gearboxes. Minimize downtime and lower operating costs.

Intelligent Automation

Intelligent automation is standard on our smartBOX to help maximize the performance of your car wash equipment. Built-in vehicle profiling and anti-collision are just two of the many standard features that enhance equipment performance and car wash quality.

Eliminate Cost and Errors

smartBOX allows you to eliminate cost and errors related to field wiring for a faster, more accurate installation, and more reliable operations.

Custom designed

Each smartBOX is custom designed for the unique requirements of each car wash.

The Perfect Blend of Durability, Reliability and Performance

Worldwide Certified

UL (USA) or CSA (Canada) certified. Also, in CE (European Union) specifications and conformity.

Heavy Duty VFD

We size VFDs and other electrical components according to the motors torque, load and operating parameters - not the hp of the motor. The right VFD increases the life of both the VFD and motor, reduces heat and helps eliminate tripping when motor torque and load is within the normal operating parameters of the motor.

Highest Quality Components

Not all electrical components are equal in quality and Laguna customers expect only the best. Our high volume and lean manufacturing allows us to offer the highest quality components at competitive pricing. Ask us about the difference.

Phase Monitoring

Monitors incoming line voltage to provide motor protection and prevent premature motor failure due to voltage and phase irregularities.

Smart Capabilities

The smartBOX equipment controller is easily expandable up to 300 outputs and 200 inputs. Features include vehicle profiling sonar, anti-collision, simulated pulse, pressure and temperature sensors and door controls.

Remote Monitoring

Monitor and record data and receive alerts onsite or remotely. BlackBox records history for enhanced diagnostics including monitoring of motors and equipment status alerts.

Modbus Option

Cost effective monitoring, alerting and adjustment of VFD motor signals through the car wash controller and HMI.

Expert Support

Designed by car wash professionals ready to support your team, every smartBOX is delivered with complete documentation and schematics.

WorldWide Certified

UL (USA) or CSA (Canada) certified. Also, in CE (European Union) specifications and conformity.

Phase Monitoring

Monitors incoming line voltage to provide motor protection and prevent premature motor failure due to voltage and phase irregularities.

Remote Monitoring

Monitor and record data and receive alerts onsite or remotely.

Black Box Recording

Black Box records operating history for enhanced diagnostics including monitoring of motors and equipment status alerts.

Built in technology

Built in technology for vehicle profiling sonar, anti-collision, simulated pulse, pressure and temperature sensors and door controls.

Main disconnect circuit breaker

Utilizes a microprocessor based over-current protective trip system.

Main disconnect mechanism

Available with through-the-door rotary handle with padlock device.

Emergency stop system

Recognizes multiple fault sources and signalizes input(s). Shuts down control voltage disabling all outputs.

Pilot light 24 VAC LED

Indicates system armed and unarmed.

UPS backup protection

Allows the ability to back-up and save all configuration data during power failure.

Ventilation system

Thermostat-controlled enclosure temperature through filtered, fan-forced airflow.

Built in wireless capability

Allows continuous monitoring of motors and email of alerts related to equipment failure.